Product Overview

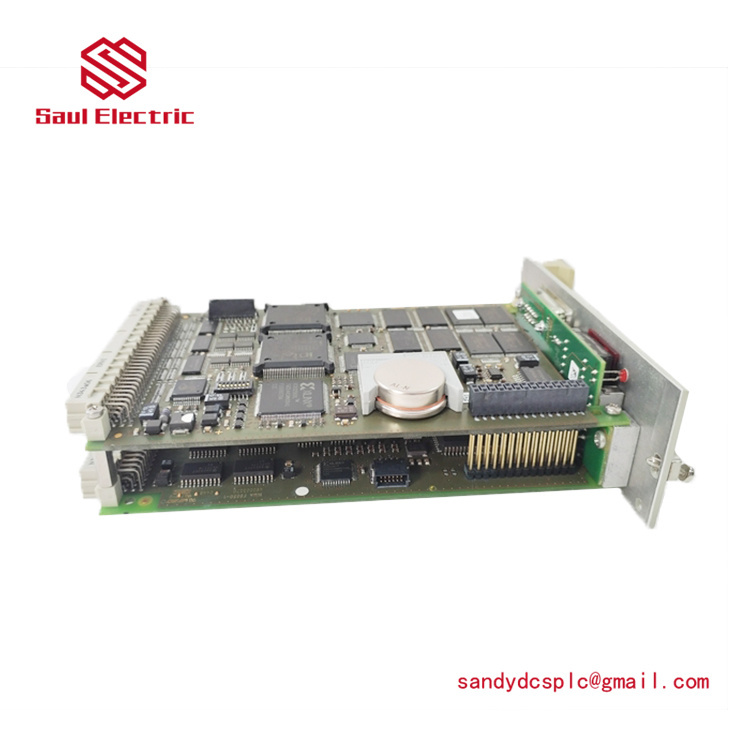

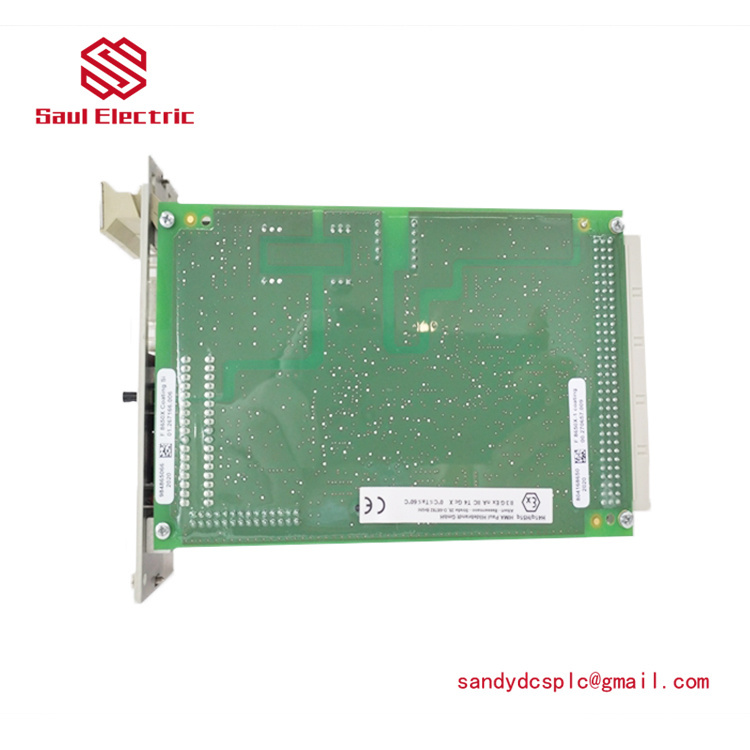

The HIMA F8650X is a programmable controller designed to meet the demands of industrial automation and safety systems. It excels in control and monitoring tasks, ensuring system safety and stability. With its advanced control algorithms and optimization technologies, it offers high precision and responsiveness, making it suitable for complex control tasks across various industries.

The HIMA F8650X is certified to SIL 3 (IEC 61508) and PL e (ISO 13849), making it ideal for high-risk applications. It features dual Intel 386EX processors operating in clock synchronization, ensuring high fault tolerance and system availability. The module also includes a four-digit alphanumeric display and LED indicators to provide detailed diagnostic information, simplifying on-site troubleshooting.

In a large-scale oil refinery, the HIMA F8650X has operated for over 8 years without a single safety-related shutdown, demonstrating exceptional reliability. It supports configurable digital and analog I/O based on application needs and is housed in high-durability material suitable for harsh industrial environments. Its compact and robust design allows for installation in tight spaces, ensuring accurate data processing and reliable control.

F8650X

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | HIMA F8650X |

| Manufacturer | HIMA |

| Product Category | Safety PLC CPU Module |

| Processor | Intel 386EX, 32-bit |

| Clock Frequency | 25 MHz |

| Memory | 1 MB Flash-EPROM (OS), 1 MB Flash-EPROM (User), 1 MB SRAM (Data) |

| Input Voltage | 24V DC |

| Output Voltage | 5V DC/2A |

| Communication Interfaces | 2 x RS485, Ethernet |

| Operating Temperature Range | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% (non-condensing) |

| Dimensions | 100mm x 75mm x 20mm |

| Weight | 0.3 kg |

| Certifications | SIL 3 (IEC 61508), PL e (ISO 13849) |

Key Features and Benefits

The HIMA F8650X boasts a high safety integrity level, being certified to SIL 3 and PL e, making it suitable for high-risk applications. Its redundant design ensures dual Intel 386EX processors operate in clock synchronization, providing high fault tolerance and system availability. The module also offers comprehensive diagnostics with a four-digit alphanumeric display and LED indicators, simplifying on-site troubleshooting.

The HIMA F8650X supports multiple communication protocols and interfaces, such as Ethernet and Modbus, enabling seamless connection and integration with other devices. It is highly scalable and can be extended and customized according to specific needs. With advanced processors and algorithms, it delivers fast and efficient data processing and control capabilities, meeting the demands of complex automation applications.

The HIMA F8650X is designed with strict quality control and reliability, having undergone rigorous testing and verification to ensure stability and dependability in harsh environments. It integrates various safety features, such as fault diagnosis, fault recovery, and security logic processing, ensuring a high level of system safety.

F8650X

Application Scenarios

The HIMA F8650X is widely used in the oil and gas industry for emergency shutdown systems (ESD) and fire and gas detection systems. In power generation, it is employed for turbine overspeed protection and generator safety interlocks. In chemical processing, it controls safety interlocks in reactors and storage tanks. In manufacturing, it ensures the safe operation of production lines. In large-scale oil refineries, it has operated for over 8 years without a single safety-related shutdown, showcasing its exceptional reliability.

Related Models

-

HIMA F8627X: An Ethernet communication module that seamlessly integrates with the HIMA F8650X.

-

HIMA F8621A: A coprocessor module that enhances system performance when paired with the HIMA F8650X.

-

HIMA F8650E: A cost-effective variant of the HIMA F8650X with slightly reduced functionality.

-

HIMA F8651X: A higher-specification model offering advanced features compared to the HIMA F8650X.

-

HIMA F8652E: A module compatible with the HIMA F8650X, providing additional functionality and flexibility.

Installation and Maintenance

Before installing the HIMA F8650X, ensure the environment meets the specified temperature and humidity requirements. Use appropriate tools and safety equipment to secure the module in place. Connect the input and output cables according to the manufacturer’s guidelines. During installation, ensure the module is securely fastened to prevent vibration-related issues. For optimal performance, the module should be installed in a clean, dry location away from sources of electromagnetic interference.

Regularly inspect the HIMA F8650X for signs of wear or damage. Keep the unit clean and free from dust to prevent overheating and ensure efficient operation. Check the connections periodically to ensure they remain secure and tight. Utilize the module’s diagnostic features to monitor its performance and address any potential issues at an early stage. Perform routine calibration of the module to maintain its accuracy and reliability. It is recommended to replace any worn or damaged components promptly to avoid system failures.

Product Warranty

The HIMA F8650X comes with a robust warranty that reflects HIMA’s confidence in the quality and reliability of its products. The warranty covers manufacturing defects and ensures the module will perform as specified under normal operating conditions for a defined period. In addition to the warranty, HIMA offers extensive global support services, including technical assistance, spare parts supply, and maintenance contracts. These services are designed to provide customers with peace of mind and ensure their automation systems operate at optimal performance levels throughout their lifecycle. HIMA’s dedicated support team is available to address any concerns and provide solutions tailored to specific needs, emphasizing its commitment to customer satisfaction.

F8650X

ABB SR511 Control system module

ABB YPK112A Analog input card

ABB IMASI23 Analog input terminal board