Key Features and Benefits

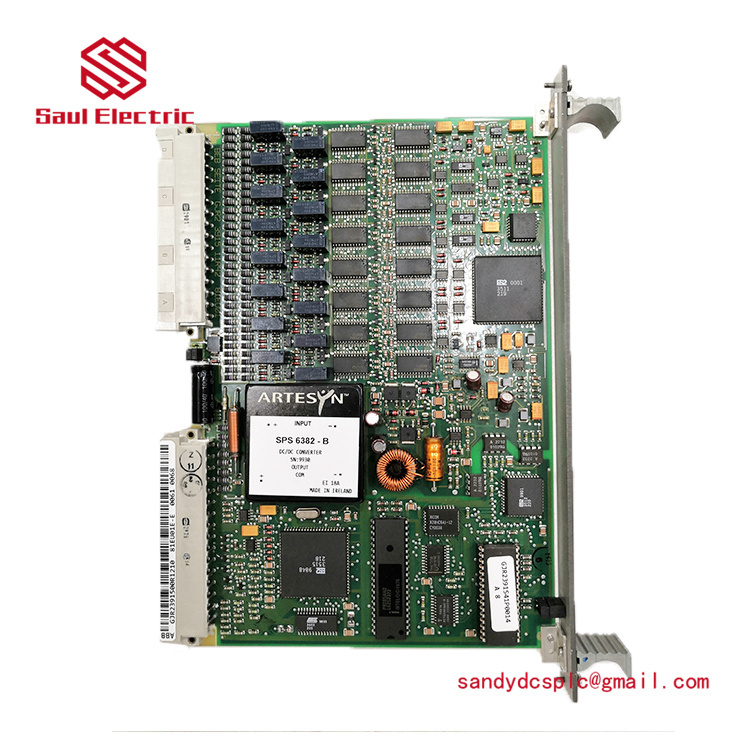

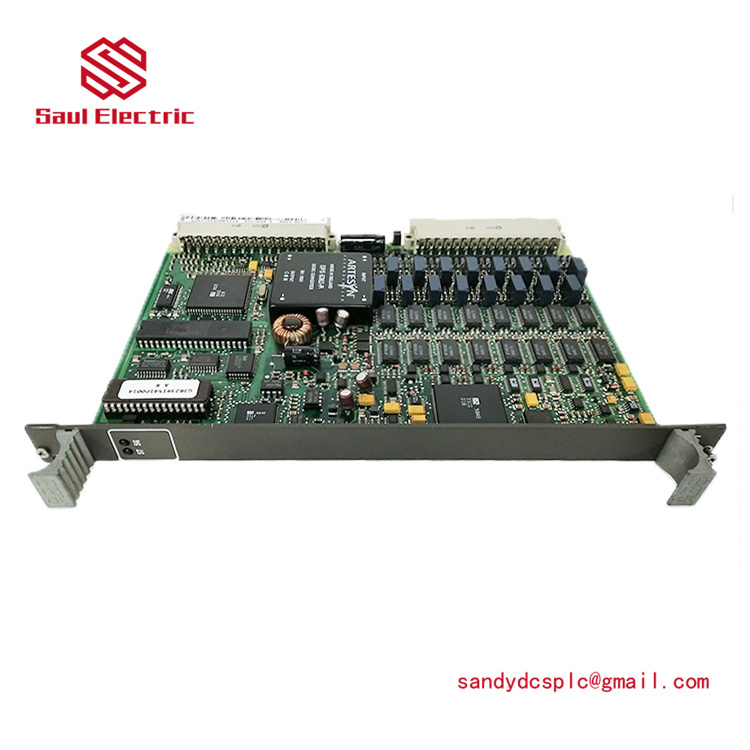

The ABB 81EU01E-E offers several practical strengths that set it apart from other vibration monitoring solutions. Its advanced signal processing algorithms ensure accurate and reliable measurement of vibration parameters, even in noisy industrial environments. The module’s wide measurement range and high accuracy make it suitable for monitoring a variety of machinery types, from small motors to large turbines. Its ability to connect with multiple vibration sensors allows for comprehensive monitoring of critical equipment. The ABB 81EU01E-E provides flexible alarm configuration, enabling users to set custom thresholds based on specific machinery requirements and operational conditions. This feature helps in early fault detection and preventive maintenance, reducing the risk of unexpected failures and extending equipment lifespan. The module’s robust industrial design, with an IP65 protection rating, ensures reliable operation in harsh environments, including those with dust, moisture, and temperature fluctuations. Its compatibility with ABB’s automation systems and support for Modbus RTU protocol simplify integration into existing control infrastructures, allowing for centralized monitoring and data analysis. The ABB 81EU01E-E also offers easy configuration and calibration through ABB’s dedicated software tools, reducing commissioning time and ensuring optimal performance from the start. Additionally, the module supports real-time data transmission, enabling operators to monitor machinery status at any time and make timely decisions. Its compact size and lightweight design make it easy to install and integrate into various automation systems.

81EU01E-E

Application Scenarios

The ABB 81EU01E-E finds extensive application across multiple industries where machinery reliability is critical. In power generation plants, it monitors vibration levels in turbines, generators, and auxiliary equipment, helping to prevent catastrophic failures and ensure uninterrupted power supply. In the oil and gas sector, the module is used to monitor pumps, compressors, and motors in refineries and pipelines, where equipment downtime can result in significant financial losses. In manufacturing facilities, the ABB 81EU01E-E is employed to monitor production line machinery, such as conveyor belts, fans, and cooling systems, ensuring smooth operations and minimizing production disruptions. In water treatment plants, it monitors pumps and valves, helping to maintain efficient water distribution and treatment processes. The module’s ability to provide real-time data enables predictive maintenance strategies, allowing maintenance teams to address potential issues before they lead to equipment failure. This proactive approach not only reduces downtime but also optimizes maintenance scheduling and resource allocation. In automotive manufacturing, the ABB 81EU01E-E monitors vibration levels in production line robots and conveyor systems, ensuring production efficiency and product quality. In the food and beverage industry, it monitors vibration in packaging machines and conveyors, helping to prevent equipment failures and ensure food safety and production continuity.

Related Models

-

ABB 81EU01E-D: Previous generation vibration monitoring module with basic functionality and slightly lower measurement accuracy.

-

ABB 81EU02E-E: Enhanced version with extended measurement range and additional diagnostic features.

-

ABB 81EU03E-E: Ruggedized variant designed for extreme temperature environments (-40°C to +85°C).

-

ABB 81EU01E-F: Wireless version with Bluetooth connectivity for remote monitoring applications.

-

ABB 81EU01E-G: High-precision variant with improved signal-to-noise ratio for critical applications.

-

ABB 81EU01E-H: Compact version with reduced dimensions for space-constrained installations.

-

ABB 81EU01E-I: Redundant configuration option for mission-critical systems requiring fail-safe operation.

-

81EU01E-E

Installation and Maintenance

Installation Preparation:

Before installing the ABB 81EU01E-E, it’s essential to prepare the site properly to ensure optimal performance and reliability. The module should be mounted on a stable surface that can support its weight and provide secure attachment using the provided DIN rail or panel mounting hardware. The mounting location should be well-ventilated and protected from direct exposure to harsh elements. Ensure that the power supply meets the module’s specifications (24 V DC ±10%) and that all connections are properly insulated and secure. When connecting vibration sensors, follow manufacturer guidelines for calibration and positioning to ensure accurate measurements. Avoid installing the module in areas with high electromagnetic interference to maintain signal integrity. It’s also important to label all connections clearly for easy identification during maintenance.

Maintenance Recommendations:

Regular maintenance of the ABB 81EU01E-E includes visual inspections for physical damage, loose connections, or signs of corrosion. Clean the module’s exterior with a dry cloth to remove dust and debris. Periodically verify sensor calibration and replace any worn or damaged sensors to ensure measurement accuracy. Check the module’s firmware version and update it as needed to benefit from the latest improvements and security patches. Perform routine diagnostic tests using ABB’s monitoring software to identify potential issues early. For optimal performance, conduct a comprehensive maintenance review at least once every six months, or more frequently in harsh operating environments. Pay attention to the module’s alarm thresholds and adjust them if necessary based on operational experience. Regularly review the module’s data logs to identify trends that may indicate developing issues. Replace any faulty components promptly to prevent system failures. If the module is used in a critical application, consider implementing redundancy to ensure continuous operation even in the event of a module failure.