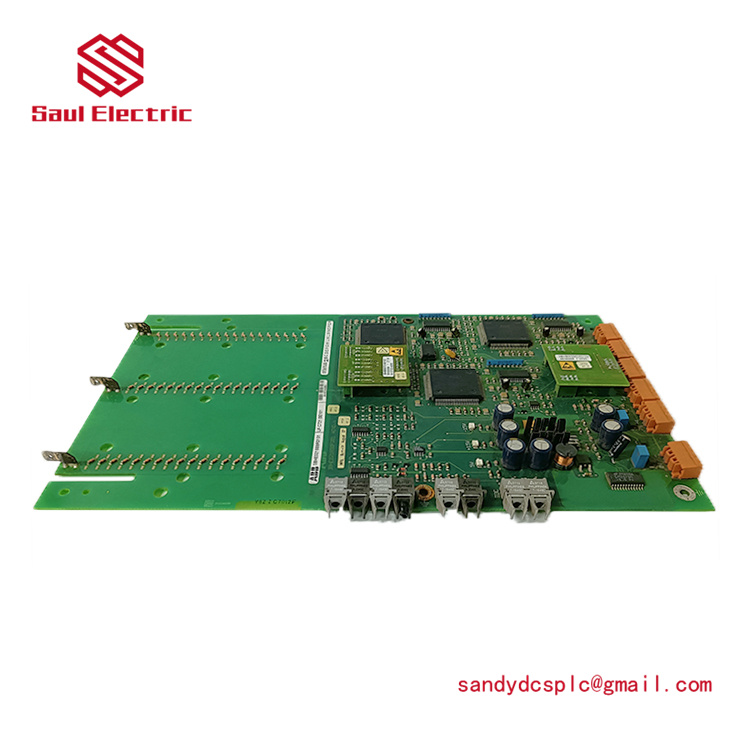

ABB UFC721BE101 Product Description

Product Overview

The ABB UFC721BE101 is a high-performance industrial communication module designed for seamless integration of automation devices into modern control systems. As part of ABB’s comprehensive portfolio of automation solutions, this module provides reliable data transmission capabilities, enabling efficient communication between field devices and central control systems. The UFC721BE101 serves as a critical interface in automation architectures, facilitating the implementation of Industry 4.0 concepts and digital transformation initiatives across various industrial sectors.

In contemporary automation environments, the ABB UFC721BE101 stands out for its ability to handle multiple communication protocols while maintaining high-speed data transmission. Its robust design supports industrial Ethernet standards, making it versatile across different applications. What truly distinguishes this module is its combination of advanced communication technology with industrial-grade durability, ensuring reliable operation even under challenging conditions.

The UFC721BE101 employs ABB’s proprietary communication optimization techniques, which minimize data latency and ensure reliable transmission of critical process information. This module supports both standard and specialized communication requirements, making it suitable for integration with a wide range of automation devices. Its compact design and flexible mounting options facilitate easy installation in control panels of varying sizes. As part of ABB’s automation solutions, the UFC721BE101 delivers exceptional value through its reliability, efficiency, and compatibility with various industrial protocols and devices.

ABB UFC721BE101

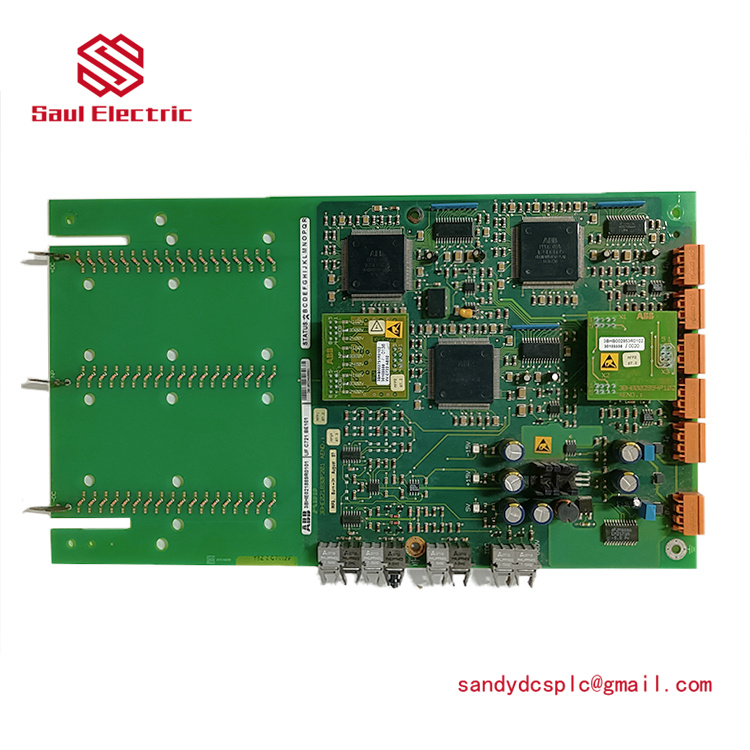

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | UFC721BE101 |

| Manufacturer | ABB |

| Product Type | Industrial Communication Module |

| Communication Protocol | EtherNet/IP, PROFINET, Modbus TCP |

| Number of Ports | 4 x 10/100Base-T(X) Ethernet ports |

| Power Supply | 24 VDC (±10%) |

| Power Consumption | 5 W maximum |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 110 mm (H) x 95 mm (W) x 55 mm (D) |

| Weight | 0.6 kg |

| Protection Rating | IP20 |

| Mounting | DIN rail (35 mm) or panel mounting |

| Compliance | CE, UL, FCC Class A |

| Certifications | ISO 9001, IEC 61000-6-2, IEC 61000-6-3 |

Key Features and Benefits

The ABB UFC721BE101 offers several distinctive features that make it an exceptional choice for industrial communication applications. Its support for multiple industrial Ethernet protocols including EtherNet/IP, PROFINET, and Modbus TCP ensures compatibility with a wide range of automation systems and devices. This multi-protocol capability eliminates the need for additional protocol conversion hardware, reducing system complexity and cost.

The module’s four high-speed Ethernet ports provide flexible connectivity options, enabling efficient network topology designs. The UFC721BE101 supports daisy-chain, star, and ring network configurations, making it adaptable to various installation requirements and helping to future-proof automation systems. Its advanced quality of service (QoS) features prioritize critical process data, ensuring timely delivery even during network congestion.

Another significant advantage is the module’s comprehensive diagnostic capabilities. The UFC721BE101 provides real-time monitoring of network performance, port status, and data traffic. These diagnostics can be accessed through ABB’s system management tools, enabling proactive maintenance and rapid troubleshooting. The ability to identify and isolate network issues quickly minimizes downtime and helps maintain production efficiency.

The UFC721BE101 also excels in its compatibility with ABB’s System 800xA platform and other industry-standard automation systems. This seamless integration ensures that the module can be easily incorporated into existing automation architectures or new greenfield installations. Its backward compatibility with previous ABB communication modules further enhances its value, protecting customers’ investments in automation infrastructure.

The module’s ruggedized design with a wide operating temperature range of -25°C to +60°C ensures reliable performance in extreme environmental conditions. Its IP20 protection rating and compliance with multiple international standards make it suitable for deployment in harsh industrial environments, including those with high humidity, dust, and vibration.

Application Scenarios

The ABB UFC721BE101 finds extensive application across various industries where reliable industrial communication is critical. In power generation facilities, the module connects turbines, generators, and auxiliary equipment to the central control system, enabling precise monitoring and control of operational parameters. Its ability to handle multiple communication protocols makes it ideal for the diverse device integration needs of modern power plants.

In the process industries, such as chemical and petrochemical plants, the UFC721BE101 facilitates communication between distributed control systems (DCS), programmable logic controllers (PLC), and field instruments. Its robust performance in harsh environments ensures uninterrupted data flow even in areas with temperature extremes and corrosive substances.

Discrete manufacturing environments benefit from the module’s efficient communication capabilities when implementing automation for production lines. The UFC721BE101 can connect robotic systems, conveyor controls, and safety interlock circuits, providing the reliable data exchange needed for high-speed manufacturing operations.

The water and wastewater treatment sector utilizes the UFC721BE101 to connect pump controls, valve actuators, and instrumentation throughout treatment facilities. Its reliability in wet and humid environments makes it suitable for the challenging conditions found in these applications.

Additionally, the UFC721BE101 is well-suited for use in mining and minerals processing operations, where it connects heavy equipment monitoring systems, conveyor controls, and safety instrumentation. Its durability withstands the severe vibration and dust present in mining environments, ensuring continuous operation despite these challenges.

UFC721BE101

Related Models

UFC718AE101 – Previous generation model with basic functionality and slightly reduced port density.

UFC721BE102 – Enhanced version featuring increased port speed and improved diagnostic capabilities.

UFC721BE103 – High-density variant offering 8 Ethernet ports in the same form factor.

UFC721BE104 – Fiber optic variant supporting long-distance communication with immunity to electrical interference.

UFC721BE105 – Wireless-enabled model supporting industrial wireless protocols for hard-to-reach locations.

UFC721BE106 – Intrinsically safe version certified for use in hazardous (Ex) areas.

UFC721BE107 – Ruggedized variant with higher temperature range for extreme environment applications.

UFC721BE108 – Redundant communication system incorporating dual modules for fail-safe operation.

UFC721BE109 – Compact version designed for space-constrained control panels with slightly reduced features.

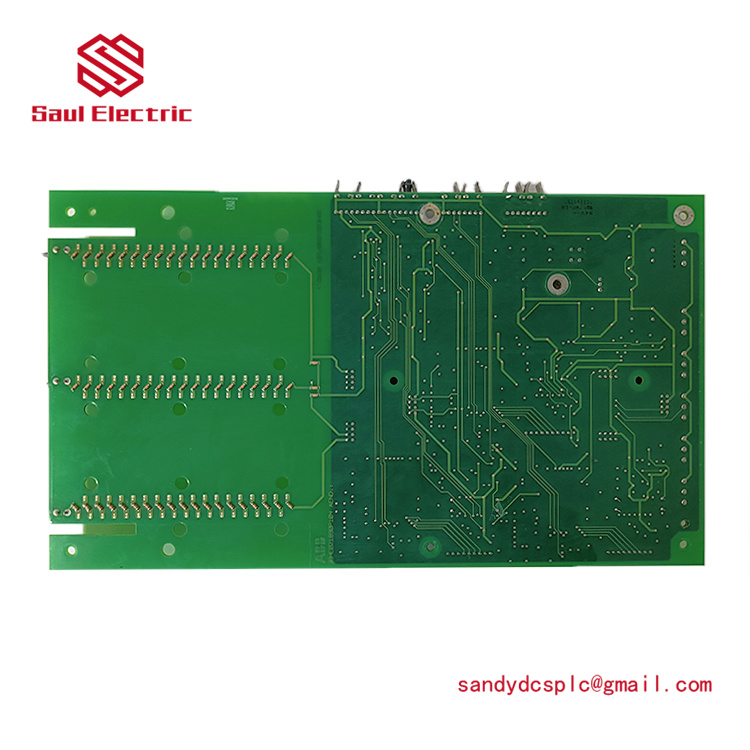

Installation and Maintenance

Proper installation of the ABB UFC721BE101 begins with selecting an appropriate location that meets environmental and electrical requirements. The module should be installed in an enclosure that protects it from direct exposure to water, excessive dust, and corrosive substances. Ensure adequate airflow around the UFC721BE101 by maintaining a minimum clearance of 15 mm on all sides.

Mount the module securely on a standard 35 mm DIN rail or panel mount using the provided hardware. All network connections should use shielded Ethernet cables with appropriate ratings to minimize electrical noise interference. Ground the system according to ABB’s installation guidelines to establish a stable reference potential and enhance noise immunity.

For optimal performance, perform regular visual inspections of the UFC721BE101 and its connections. Check for signs of overheating, corrosion, or physical damage. Test network connectivity and data transmission rates periodically using ABB’s diagnostic tools to verify proper operation and communication quality. The module’s built-in diagnostics can identify developing issues before they impact system functionality.

In harsh environments, implement a scheduled maintenance program that includes cleaning the module’s exterior and checking terminal connections biannually. Replace the UFC721BE101 after approximately 8–10 years of service or sooner if performance degradation is observed, ensuring continued reliability in critical automation applications.

Product Warranty

ABB backs the UFC721BE101 with a comprehensive warranty program that reflects our confidence in the product’s quality and performance. The standard warranty covers manufacturing defects and workmanship for a period of three years from the date of purchase. This coverage includes necessary repairs or replacement of the module to maintain its specified performance characteristics.

In addition to the standard warranty, ABB offers extended warranty options that can extend coverage up to seven years, providing customers with additional protection and peace of mind. Support services include global technical assistance through ABB’s network of automation experts, who can provide troubleshooting guidance, installation support, and system integration advice.

UFC721BE101

ABB CAI04 Communication card

ABB 3ASC25H208 DATX100 Distributed I/O module

ABB 3ASC25H214 DATX130 Servo motor