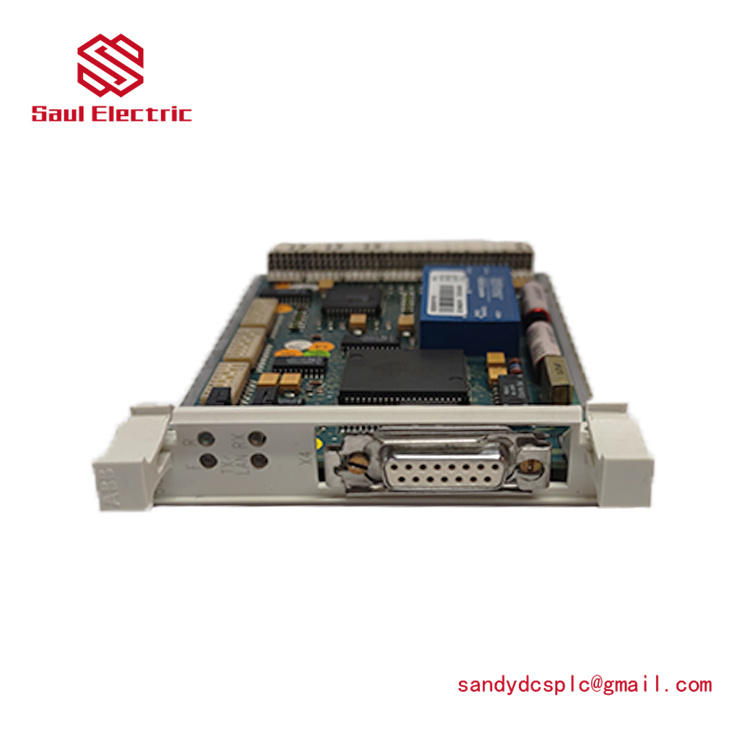

ABB CS513 Safety Module Product Description

Product Overview

The ABB CS513 is a high-performance safety module designed for critical automation applications where reliability and precision are paramount. As part of ABB’s comprehensive automation portfolio, the CS513 integrates seamlessly into safety systems, providing a robust solution for process monitoring, emergency shutdown, and safety interlocking. Its core functionality revolves around ensuring compliance with safety standards (e.g., IEC 61508 SIL 3) while enabling efficient control of hazardous processes.

The CS513 is engineered to operate in demanding industrial environments, such as power plants, chemical facilities, and oil & gas operations. Its compact design and modular architecture make it ideal for both standalone safety applications and integration with larger distributed control systems (DCS). By combining ABB’s advanced safety logic algorithms with diagnostic capabilities, the CS513 minimizes downtime risks and enhances operational safety.

What sets the ABB CS513 apart is its ability to handle up to 16 safety functions simultaneously, ensuring redundancy and fault tolerance. Its rugged construction and compliance with international certifications (e.g., ATEX, IECEx) further solidify its role as a trusted component in mission-critical infrastructure.

CS513

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | CS513 |

| Manufacturer | ABB |

| Product Type | Safety Logic Controller Module |

| Power Supply | 24V DC ±10% |

| Input Voltage Range | 20–30V DC |

| Dimensions | 160 x 200 x 60 mm (W x H x D) |

| Weight | 2.5 kg |

| Communication | Ethernet/IP, Modbus TCP, Profibus DP |

| Operating Temp | -25°C to +70°C |

| Mounting | DIN rail or panel mounting |

| Protection Class | IP54 |

| Certifications | SIL 3, ATEX, IECEx, CSA |

Key Features and Benefits

The ABB CS513 excels in several critical areas that elevate its value in industrial automation:

1. Advanced Safety Functionality

The CS513 supports 16 independent safety functions, enabling complex safety scenarios such as emergency shutdown, speed monitoring, and access control. Its real-time diagnostics detect faults within milliseconds, ensuring compliance with SIL 3 standards.

The CS513 supports 16 independent safety functions, enabling complex safety scenarios such as emergency shutdown, speed monitoring, and access control. Its real-time diagnostics detect faults within milliseconds, ensuring compliance with SIL 3 standards.

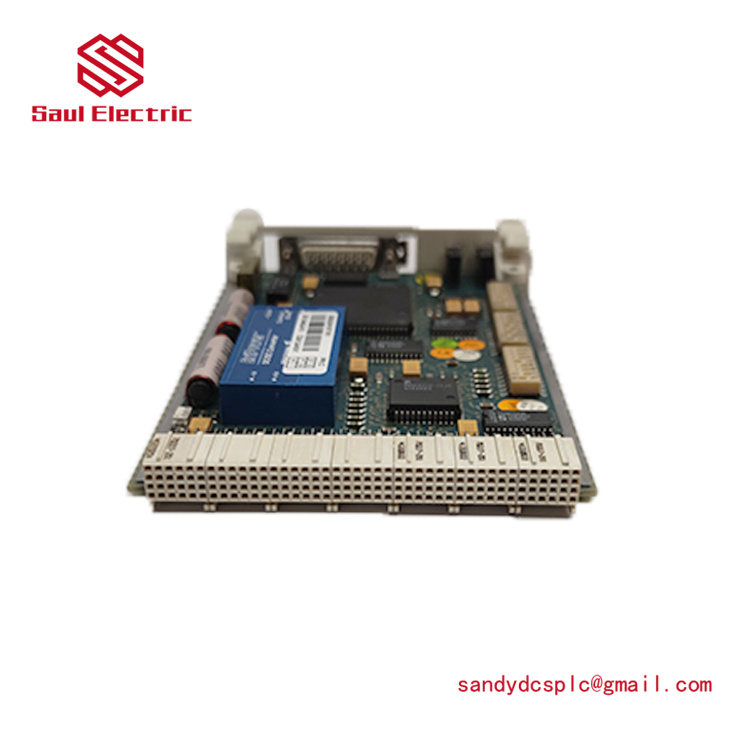

2. Dual-Channel Architecture

Featuring redundant processing channels, the CS513 achieves fail-safe operation even under hardware or software faults. This dual-channel design eliminates single points of failure, critical for high-risk applications.

Featuring redundant processing channels, the CS513 achieves fail-safe operation even under hardware or software faults. This dual-channel design eliminates single points of failure, critical for high-risk applications.

3. Flexible Integration

With compatibility with ABB’s AC800M controllers and third-party PLCs, the CS513 simplifies system expansion. Its open communication protocols (e.g., Ethernet/IP) streamline integration into existing infrastructures.

With compatibility with ABB’s AC800M controllers and third-party PLCs, the CS513 simplifies system expansion. Its open communication protocols (e.g., Ethernet/IP) streamline integration into existing infrastructures.

4. Ruggedized Design

Built to withstand vibration, shock, and temperature extremes, the CS513 is certified for use in hazardous areas (Zone 2/Division 2). Its IP54-rated housing protects against dust and water ingress.

Built to withstand vibration, shock, and temperature extremes, the CS513 is certified for use in hazardous areas (Zone 2/Division 2). Its IP54-rated housing protects against dust and water ingress.

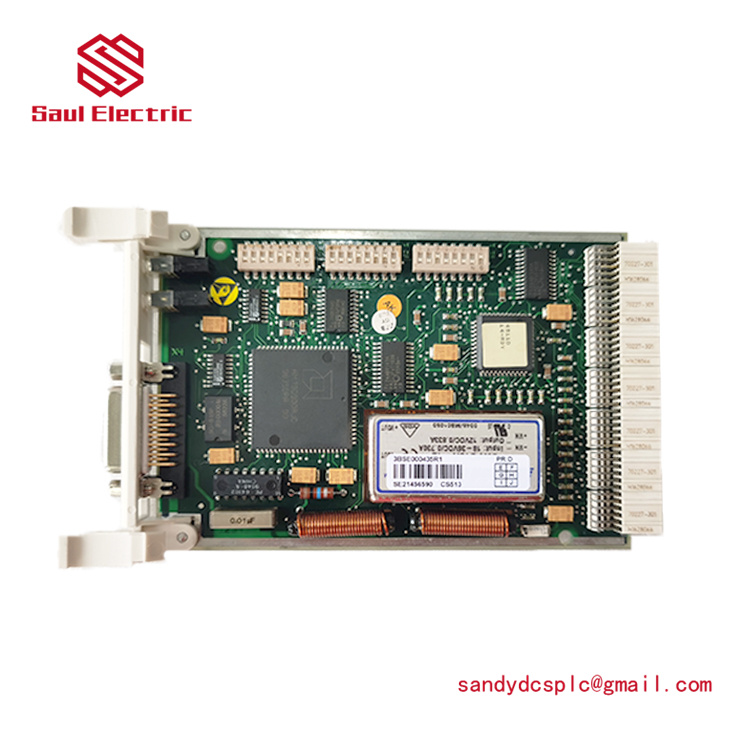

5. User-Centric Diagnostics

LED indicators and onboard diagnostics reduce troubleshooting time. The ABB Safety Suite software provides remote monitoring, historical logging, and configuration tools.

LED indicators and onboard diagnostics reduce troubleshooting time. The ABB Safety Suite software provides remote monitoring, historical logging, and configuration tools.

Application Scenarios

The ABB CS513 is widely deployed in industries requiring stringent safety protocols:

1. Power Generation

In thermal power plants, the CS513 safeguards turbine overspeed conditions and boiler safety loops. Its rapid response prevents equipment damage and ensures compliance with emission regulations.

In thermal power plants, the CS513 safeguards turbine overspeed conditions and boiler safety loops. Its rapid response prevents equipment damage and ensures compliance with emission regulations.

2. Oil & Gas Refineries

For flare stack ignition controls and gas leak detection, the CS513 manages safety instrumented systems (SIS) to mitigate explosion risks.

For flare stack ignition controls and gas leak detection, the CS513 manages safety instrumented systems (SIS) to mitigate explosion risks.

3. Chemical Processing

During batch production, the CS513 monitors reactor temperatures and pressure to trigger emergency shutdowns, preventing runaway reactions.

During batch production, the CS513 monitors reactor temperatures and pressure to trigger emergency shutdowns, preventing runaway reactions.

4. Mining Operations

In conveyor belt systems, the CS513 enforces emergency stop commands and personnel safety interlocks, reducing accident rates.

In conveyor belt systems, the CS513 enforces emergency stop commands and personnel safety interlocks, reducing accident rates.

CS513

Related Models

-

3HAC15 1101-7 – Previous-generation safety module with basic function blocks

-

3HAC15 1013 – Expansion module for input/output channels compatible with CS513

-

3HAC15 3111 – High-density variant for space-constrained applications

-

AC800M – Core controller for building distributed safety architectures

-

3HAC15 2002 – Safety I/O module for analog signal processing

Installation and Maintenance

Installation Preparation

Ensure the installation area meets the CS513’s operating temperature range (-25°C to +70°C) and is free of conductive contaminants. Mount the module on a DIN rail using the provided brackets, ensuring proper ventilation. Secure all ground connections to a common earth point to prevent EMI interference.

Ensure the installation area meets the CS513’s operating temperature range (-25°C to +70°C) and is free of conductive contaminants. Mount the module on a DIN rail using the provided brackets, ensuring proper ventilation. Secure all ground connections to a common earth point to prevent EMI interference.

Maintenance Recommendations

Conduct biannual inspections of terminal connections and clean dust accumulation from the housing. Perform firmware updates via ABB’s Safety Suite to access the latest safety upgrades. Replace lithium batteries every 5 years to maintain backup functionality.

Conduct biannual inspections of terminal connections and clean dust accumulation from the housing. Perform firmware updates via ABB’s Safety Suite to access the latest safety upgrades. Replace lithium batteries every 5 years to maintain backup functionality.

Product Warranty

The ABB CS513 is backed by a 2-year global warranty covering manufacturing defects and performance issues. ABB’s technical support team provides 24/7 assistance for troubleshooting and firmware updates. Customers receive lifetime access to safety compliance documentation and training resources to maximize the module’s operational efficiency. This comprehensive support underscores ABB’s commitment to delivering reliable, future-proof safety solutions.