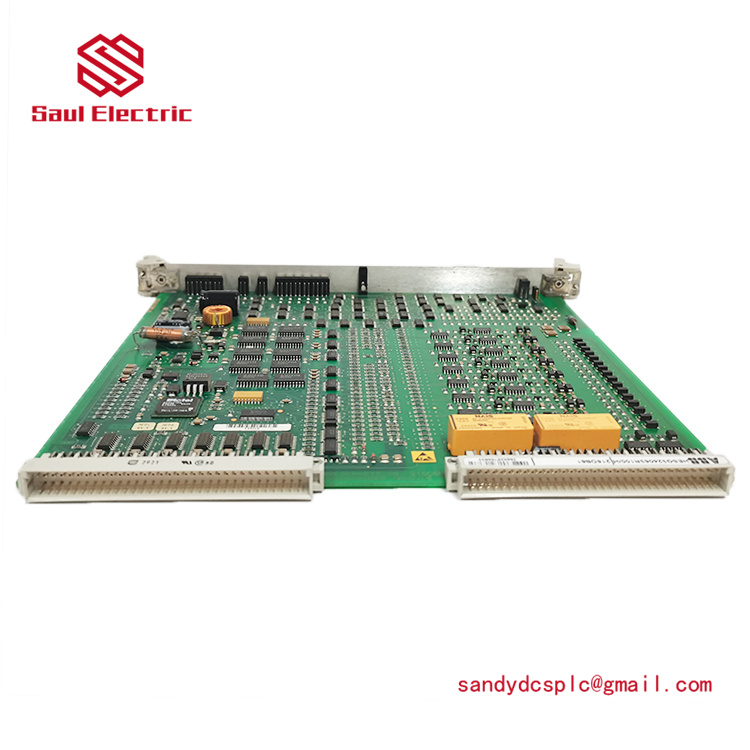

ABB 216DB61 Product Description

Product Overview

The ABB 216DB61 is a high-performance communication module designed for seamless integration within ABB’s industrial automation systems. As a critical component of ABB’s AC 500 series programmable logic controllers (PLCs), this module enables efficient data exchange between controllers, remote I/O devices, and higher-level systems. The 216DB61 plays a pivotal role in modern automation setups by providing reliable communication infrastructure that enhances system responsiveness and operational visibility.

In industrial control applications, the 216DB61 serves as a bridging element that connects PLCs to various networks and devices, facilitating the flow of critical process data. Its advanced protocol support ensures compatibility with multiple industrial standards, making it an versatile asset for complex automation architectures. The module’s compact design and robust performance characteristics make it particularly valuable for applications where space is limited but reliability and speed are paramount.

The 216DB61 stands out for its ability to handle high-speed data transmission while maintaining exceptional signal integrity. This ensures minimal latency in control systems, which is crucial for time-sensitive operations such as manufacturing processes and infrastructure management. By incorporating the 216DB61 into automation setups, industries can achieve enhanced system coordination, improved diagnostic capabilities, and streamlined maintenance procedures.

ABB 216DB61

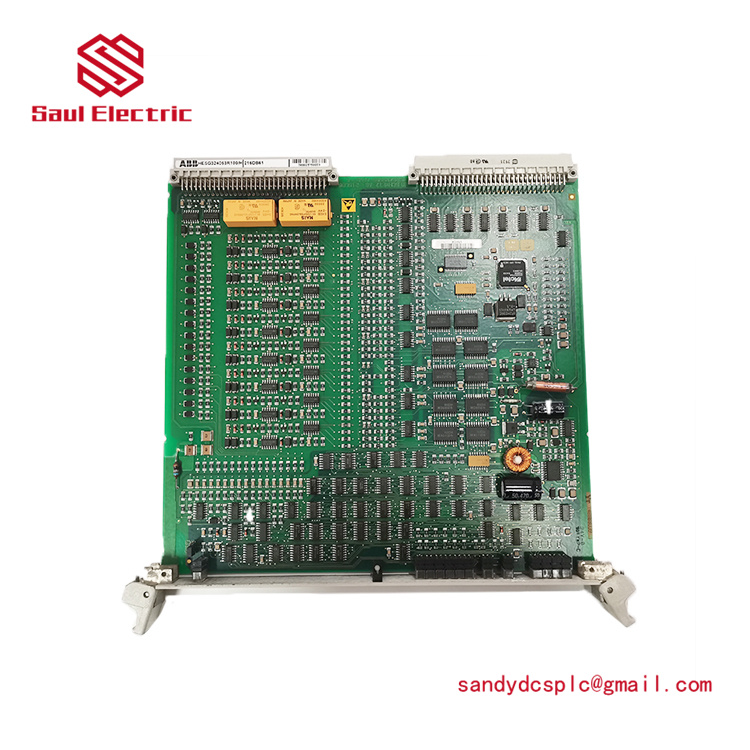

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 216DB61 |

| Manufacturer | ABB |

| Product Type | Communication Module |

| Communication Protocols | PROFIBUS DP, MODBUS RTU |

| Data Transfer Rate | Up to 12 Mbps |

| Memory Capacity | 64 KB |

| Dimensions (HxWxD) | 100 x 50 x 80 mm |

| Weight | 0.4 kg |

| Housing Material | Polycarbonate (UL 94 V-0) |

| Protection Rating | IP20 |

| Ambient Temperature | -25°C to +60°C |

| Mounting | DIN rail (35 mm) |

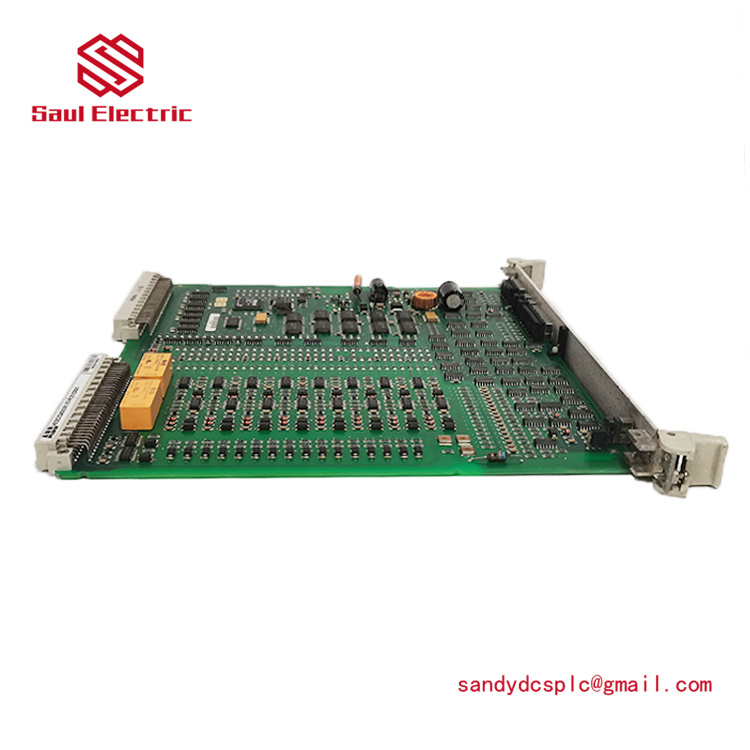

Key Features and Benefits

The ABB 216DB61 offers several features that make it a preferred choice for industrial communication applications. Its support for multiple industrial protocols, including PROFIBUS DP and MODBUS RTU, ensures broad compatibility with existing automation systems and devices. This versatility allows the 216DB61 to serve as a universal communication solution across diverse industrial environments.

The module’s high-speed data transfer capability of up to 12 Mbps ensures rapid transmission of control signals and process data, reducing system latency and improving overall efficiency. This is particularly beneficial in applications requiring real-time monitoring and control, such as robotic assembly lines and process automation systems.

Another key advantage of the 216DB61 is its robust diagnostic capabilities. Equipped with comprehensive status indicators and error-detection features, the module simplifies troubleshooting and maintenance. Its intuitive LED indicators provide clear visual feedback on communication status, network activity, and potential faults, enabling quick identification and resolution of issues.

The 216DB61 also benefits from ABB’s focus on durability. Its polycarbonate housing provides excellent protection against dust, moisture, and mechanical stress, ensuring reliable operation in challenging industrial conditions. The module’s wide operating temperature range further enhances its suitability for deployment in various environments, from indoor control rooms to outdoor installations.

Application Scenarios

The ABB 216DB61 finds extensive use across multiple industries due to its versatility and reliability. In automotive manufacturing, it connects PLCs to robotic controllers and sensor networks on assembly lines, enabling precise coordination of welding, painting, and assembly operations.

In oil & gas refineries, the 216DB61 facilitates communication between PLCs and remote I/O modules installed in hazardous areas, transmitting critical data about pressure, temperature, and flow rates to central control systems. Its protocol flexibility makes it ideal for integrating legacy equipment with modern automation systems.

In power generation facilities, the 216DB61 connects turbine control systems to supervisory control and data acquisition (SCADA) networks, providing real-time monitoring of generator performance and enabling rapid response to operational changes.

The communication module is also widely used in smart infrastructure applications, such as traffic management systems and water treatment plants, where it connects field devices to central control centers, ensuring efficient operation and timely response to system events.

16DB61

Related Models

216DB62 – Enhanced variant with additional Ethernet support for IIoT applications.

216DB60 – Previous generation model with limited protocol support.

216DB63 – High-density variant supporting multiple communication channels.

216DB61M – Ruggedized version with extended temperature range for extreme environments.

216DB61L – Compact variant for space-constrained control panels.

216DB61S – Smart variant with integrated security features for industrial cybersecurity.

216DB60 – Previous generation model with limited protocol support.

216DB63 – High-density variant supporting multiple communication channels.

216DB61M – Ruggedized version with extended temperature range for extreme environments.

216DB61L – Compact variant for space-constrained control panels.

216DB61S – Smart variant with integrated security features for industrial cybersecurity.

Installation and Maintenance

Before installing the ABB 216DB61, ensure the control panel meets IP20 protection standards and provides adequate ventilation. Mount the module on a 35 mm DIN rail, maintaining at least 10 mm of clearance between adjacent modules to facilitate heat dissipation. Grounding should comply with IEC 61131-2 requirements to minimize electrical noise interference.

For optimal performance, maintain the ambient temperature within the -25°C to +60°C range. Regular maintenance includes quarterly inspections of terminal connections and LED indicators. Clean terminal blocks with a damp cloth if corrosion is detected, and replace the 216DB61 if persistent communication faults are indicated. Firmware updates should be applied via ABB’s dedicated engineering tools during scheduled downtime.

Product Warranty

The ABB 216DB61 is backed by a comprehensive 24-month warranty covering manufacturing defects and functional failures under normal operating conditions. ABB provides global technical support through its certified service centers, offering remote diagnostics and on-site assistance for rapid resolution of issues.

16DB61