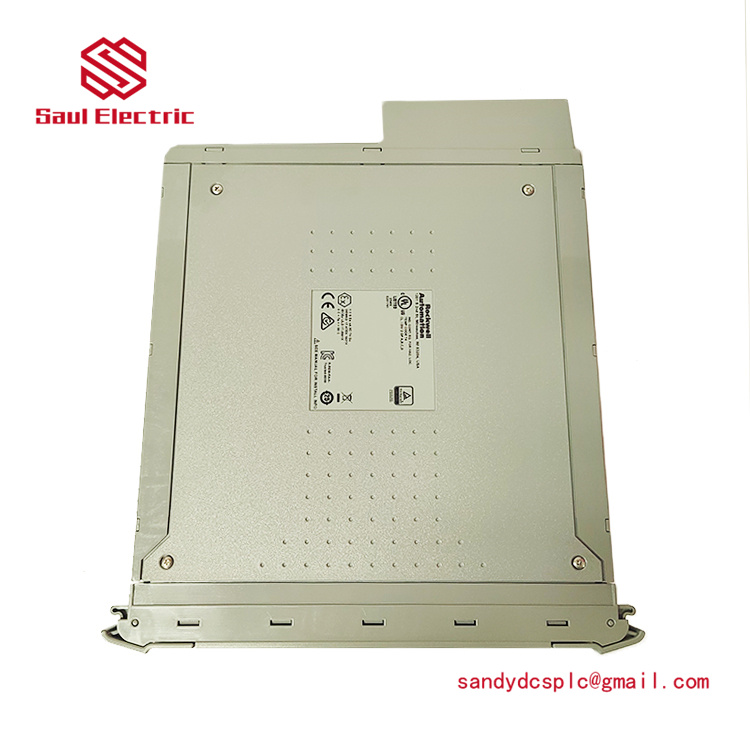

TRICONEX 8111 Product Description

Product Overview

The TRICONEX 8111 is a high-performance, fault-tolerant controller designed for safety-critical applications in industrial automation systems. As part of TRICONEX’s renowned 8000 Series, this controller provides reliable and precise control for safety instrumented systems (SIS) and emergency shutdown systems (ESD). Its core functionality lies in executing safety Instrumented functions (SIF) with a triple modular redundant (TMR) architecture, ensuring high availability and fault tolerance. The TRICONEX 8111 is widely recognized for its exceptional reliability and stability, making it an ideal choice for industries where safety and uptime are paramount. With a processing speed of up to 100 milliseconds and support for up to 1024 I/O points, it can handle complex safety applications efficiently. The controller supports multiple communication protocols such as HART, Modbus, and Profibus, enabling seamless integration with various field devices and control systems. The TRICONEX 8111 is designed to meet stringent safety standards, including SIL 3 (IEC 61508) and ISA S84.01, ensuring compliance with international safety requirements. Its rugged construction and wide operating temperature range (-20°C to +60°C) allow it to operate reliably in harsh industrial environments. The TRICONEX 8111 is widely used in oil and gas, chemical, power generation, and other industries, providing critical safety protection and ensuring stable production operations.

T8111C

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | TRICONEX 8111 |

| Manufacturer | TRICONEX |

| Product Type | Fault-Tolerant Safety Controller |

| Processing Speed | Up to 100 milliseconds |

| I/O Capacity | Up to 1024 I/O points |

| Communication Protocols | HART, Modbus, Profibus |

| Memory | 4MB of user memory |

| Power Supply | 24 VDC ±10% |

| Operating Temperature | -20°C to +60°C |

| Dimensions (W x H x D) | 19-inch rack-mounted, 5.25 x 17.5 x 12 inches |

| Weight | 12 kg |

| Protection Rating | IP20 |

| Certification | SIL 3 (IEC 61508), ISA S84.01 |

Key Features and Benefits

The TRICONEX 8111 excels in environments demanding high reliability and safety. Its triple modular redundant (TMR) architecture ensures that even in the event of a single-point failure, the system continues to operate without interruption, providing 99.9% availability. The controller’s fast processing speed of up to 100 milliseconds enables rapid response to safety events, reducing potential risks and losses. With support for up to 1024 I/O points, the TRICONEX 8111 can handle complex safety applications, making it suitable for large-scale industrial facilities. Its comprehensive diagnostic capabilities continuously monitor system health, providing early warnings for potential issues and reducing unplanned downtime. The controller supports multiple communication protocols, including HART, Modbus, and Profibus, ensuring seamless integration with various field devices and control systems. The TRICONEX 8111’s rugged construction and wide operating temperature range (-20°C to +60°C) allow it to operate reliably in harsh industrial environments. Its user-friendly programming interface simplifies configuration and maintenance, reducing engineering time and operational costs. The controller’s compliance with stringent safety standards, including SIL 3 (IEC 61508) and ISA S84.01, ensures that users can deploy it with confidence in safety-critical applications.

Application Scenarios

In oil and gas refineries, the TRICONEX 8111 is widely used for emergency shutdown systems (ESD) and fire and gas detection systems (FGS). For example, in a major offshore oil platform, the TRICONEX 8111 controller monitors critical parameters such as pressure, temperature, and gas concentration. Upon detecting abnormal conditions, it immediately triggers emergency shutdown procedures, preventing potential accidents and ensuring personnel and facility safety. In chemical plants, the controller manages safety interlock systems for reactors and storage tanks, preventing overpressure, overheating, and leaks. In power generation facilities, it protects turbines and boilers by monitoring critical parameters and implementing protective actions when necessary. In pharmaceutical manufacturing, the TRICONEX 8111 ensures compliance with strict safety and quality standards, safeguarding production processes and product quality. Additionally, it is applied in industries such as metallurgy, automotive manufacturing, and food processing, providing reliable safety protection and ensuring stable production operations.

T8111C

Related Models

-

TRICONEX 8101 – Previous generation model with basic functionality, suitable for smaller safety applications.

-

TRICONEX 8121 – Upgraded model offering enhanced performance and expanded I/O capacity compared to the TRICONEX 8111.

-

TRICONEX 8111R – Ruggedized variant designed for extreme environments with extended temperature range (-40°C to +70°C).

-

TRICONEX 8111E – Enhanced version with improved diagnostic capabilities and communication protocols.

-

TRICONEX 8111C – Compact version with reduced dimensions for space-constrained installations.

-

TRICONEX 8111H – High-capacity variant supporting up to 2048 I/O points for large-scale safety applications.

-

TRICONEX 8111S – Simplified model with basic features, ideal for cost-effective solutions in smaller safety systems.

-

TRICONEX 8111X – Extended functionality variant supporting advanced safety protocols and integration capabilities.

Installation and Maintenance

Before installing the TRICONEX 8111, ensure the installation environment meets the required temperature and humidity specifications. Mount the controller in a 19-inch standard rack with adequate airflow clearance to prevent overheating. Ground the controller properly to protect against electromagnetic interference and ensure stable operation. Avoid exposing the controller to water, dust, or corrosive gases to prolong its service life. Verify voltage compatibility before powering up and use surge protectors for input/output circuits in areas prone to lightning. For maintenance, regularly inspect connectors for loose wiring and clean the controller’s ventilation openings to prevent dust accumulation. Replace the controller every 10 years (or as per manufacturer guidelines) to maintain optimal performance.

Product Warranty

TRICONEX provides a 3-year limited warranty for the TRICONEX 8111, covering manufacturing defects and performance issues. Global support teams are available 24/7 to offer technical assistance, including remote diagnostics and on-site service for critical failures. Extended warranty plans can be purchased to extend the asset lifecycle. TRICONEX’s commitment to quality ensures the controller meets stringent industry standards, minimizing total cost of ownership and maximizing operational uptime. Customers can rely on TRICONEX’s extensive global network for prompt support and reliable service, ensuring long-term satisfaction and confidence in their automation investments.

T8111C