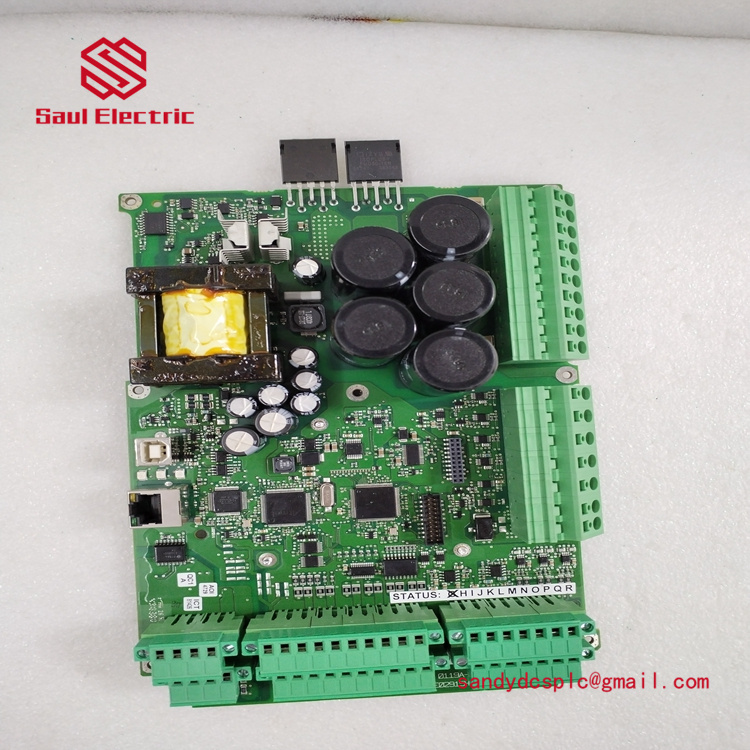

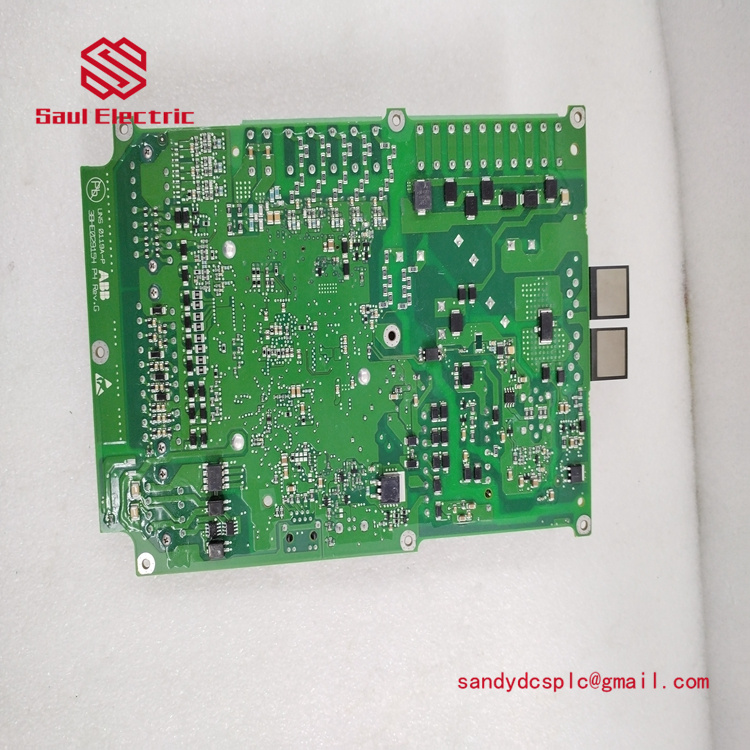

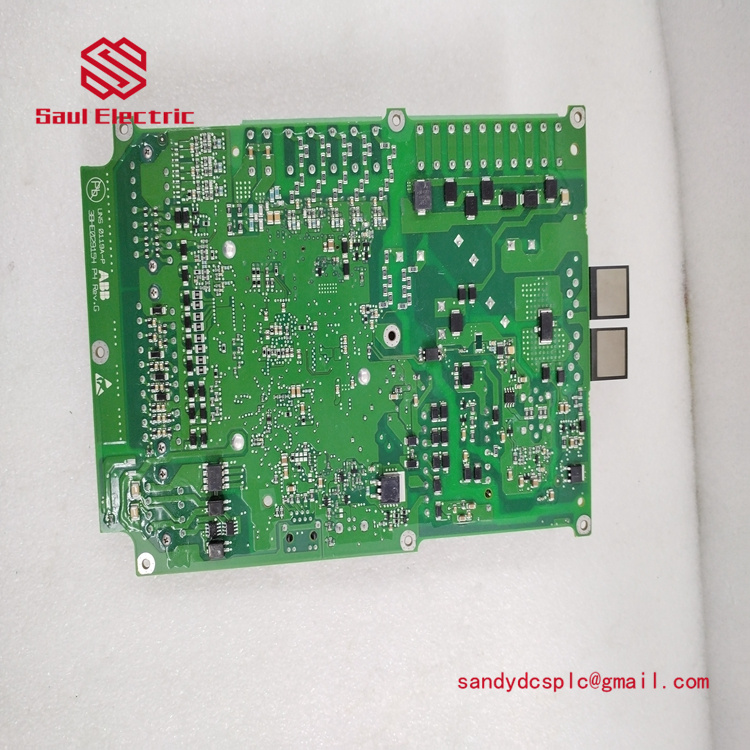

ABB UNS0119A-P V101 Product Description

Product Overview

The ABB UNS0119A-P V101 is a high-performance digital input module designed for industrial automation systems. Built with industrial-grade components, it offers a mean time between failures (MTBF) of over 100,000 hours, ensuring continuous operation in harsh environments. As part of ABB’s extensive automation portfolio, this module integrates seamlessly with major PLC systems such as ABB, Siemens, and Allen-Bradley, providing reliable performance and ease of integration across various control architectures. Its core functionality lies in reading the on/off states of external devices like sensors, switches, and pushbuttons, and transmitting this information to PLCs for control purposes. With 8 configurable digital inputs (sourcing/sinking) and 8 relay outputs, it supports diverse sensor and actuator types, making it ideal for applications requiring flexible I/O expansion. The ABB UNS0119A-P V101 also features advanced signal conditioning, including noise filtering and surge protection (2kV isolation), ensuring stable signal transmission even in high-interference environments. Its plug-and-play design with DIN rail mounting simplifies installation and reduces downtime. Low power consumption (≤5W) further lowers operational costs, especially in large-scale systems. The ABB UNS0119A-P V101 is widely adopted in industries such as manufacturing, energy, and process control, ensuring optimal efficiency and safety in automation workflows .

ABB UNS0119A-P V101

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB UNS0119A-P V101 |

| Manufacturer | ABB |

| Product Type | Digital Input Module |

| Voltage | 24V DC (±10%) |

| Current Rating | 0.5A (per channel) |

| Interface Type | Digital I/O (16 channels: 8 inputs/8 outputs) |

| Compatibility | Compatible with PLC systems (e.g., ABB, Siemens, Allen-Bradley) |

| Communication Protocol | Modbus RTU, Profibus DP |

| Operating Temperature | -20°C to +60°C |

| Dimensions (W x H x D) | 100 mm x 150 mm x 50 mm |

| Weight | 0.8 kg |

| Protection Rating | IP20 |

| Mounting Type | DIN rail mounting |

| Input Type | Dry contact (voltage-free) inputs |

| Output Type | Relay outputs |

| Certification | CE, UL, ISO 9001 |

Key Features and Benefits

The ABB UNS0119A-P V101 excels in environments demanding precise digital signal processing and reliable operation. Its industrial-grade components ensure an MTBF exceeding 100,000 hours, making it suitable for long-term use in harsh conditions. The module’s 8 configurable digital inputs and 8 relay outputs offer flexible I/O configuration, accommodating various sensor and actuator types. Advanced signal conditioning technology minimizes interference from external noise and prevents signal distortion, ensuring stable data transmission. The plug-and-play design with DIN rail mounting simplifies installation and reduces commissioning time, while the low power consumption of ≤5W helps lower operational costs in large-scale automation systems.

The ABB UNS0119A-P V101 supports multiple communication protocols, including Modbus RTU and Profibus DP, enabling seamless integration with diverse PLC systems. Its compact dimensions (100 mm x 150 mm x 50 mm) and lightweight design (0.8 kg) make it ideal for space-constrained installations. The module also features status indication LEDs that display the on/off state of each input channel, facilitating quick troubleshooting. With its superior noise immunity (2kV isolation) and higher channel density (16 I/O channels in a compact form factor), the ABB UNS0119A-P V101 outperforms many competing products on the market. Its long lifespan and reliability reduce maintenance frequency and costs, ensuring consistent performance over extended periods .

Application Scenarios

In manufacturing plants, the ABB UNS0119A-P V101 is widely used in assembly lines and robotic systems. For instance, a major automotive factory in Germany integrated this module into its robotic welding line. The module’s high-speed response (≤1ms) and reliable signal processing reduced downtime by 15% and improved weld quality consistency. The flexible I/O configuration also allowed seamless integration with existing PLCs, saving $20,000 in retrofit costs. In power plants, it monitors the status of switches and sensors in turbine control systems, ensuring stable operation and timely fault detection. For oil and gas refineries, the module controls valves and pumps in process automation, providing precise input signal processing to prevent leaks and ensure safety. In water and wastewater treatment facilities, it manages pump control and flow monitoring, ensuring efficient water distribution and treatment processes .

UNS0119A-P V101

Related Models

-

ABB UNS0119A-P V102 – Enhanced version with extended temperature range (-40°C to +70°C) for extreme environments.

-

ABB UNS0119A-P V100 – Basic model with fewer I/O channels (4 inputs/4 outputs) for small-scale applications.

-

ABB 3BHE029153R0101 – Companion module offering analog input capabilities for mixed signal processing.

-

ABB 3BHE029154P3 – Higher-power variant designed for heavy-duty industrial applications.

-

ABB UNS0119A-P V101R – Ruggedized version with IP67 protection for outdoor and wet environments.

-

Siemens SM321 – Competing digital input module with similar I/O configuration and functionality.

-

Allen-Bradley 1756-IB16 – Comparable module offering 16 digital inputs for Rockwell Automation systems.

-

ABB UNS0119A-P V101E – Energy-efficient variant with optimized power management features.

-

ABB UNS0119A-P V101C – Compact version with reduced dimensions for space-limited installations.

Installation and Maintenance

Before installing the ABB UNS0119A-P V101, ensure the operating environment meets temperature and humidity specifications. Mount the module on a DIN rail with adequate airflow clearance to prevent thermal throttling. Ground the chassis to shield against electromagnetic interference, and avoid exposing the module to water, dust, or corrosive gases. Verify voltage compatibility before powering up and use surge protectors for input/output circuits in lightning-prone areas. For maintenance, regularly inspect connectors for loose wiring and clean the module’s ventilation openings to prevent dust accumulation. Replace the module every 10 years (or as per manufacturer guidelines) to maintain optimal performance .

Product Warranty

ABB provides a 1-year limited warranty for the ABB UNS0119A-P V101, covering manufacturing defects and performance issues. Global support teams offer 24/7 technical assistance, including remote diagnostics and on-site service for critical failures. Extended warranty plans are available to extend asset lifecycle. ABB’s commitment to quality ensures the module meets stringent industry standards, minimizing total cost of ownership and maximizing operational uptime. Customers can rely on ABB’s extensive global network for prompt support and reliable service, ensuring long-term satisfaction and confidence in their automation investments .

UNS0119A-P V101