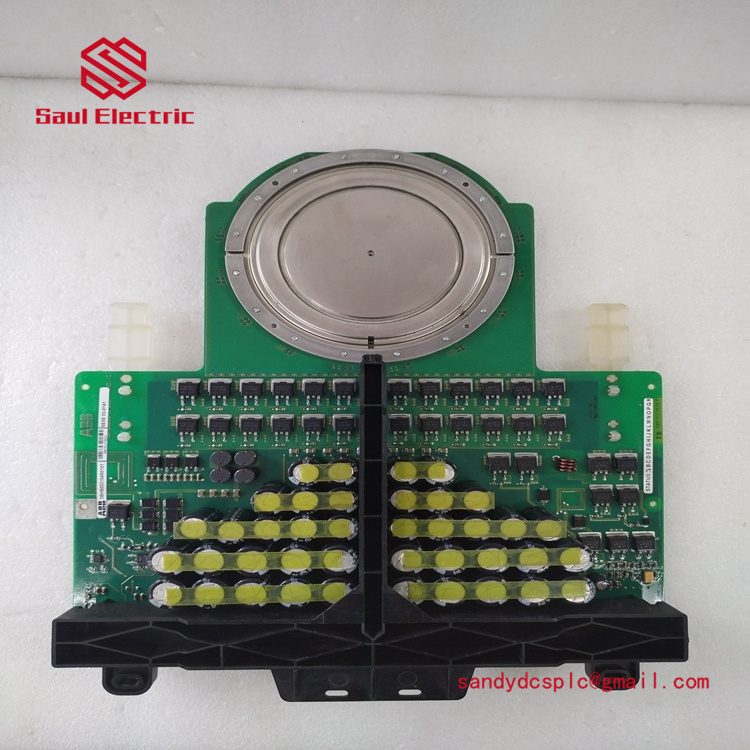

ABB 5SHX2645L0004 Product Description

Product Overview

The ABB 5SHX2645L0004 is a high-performance servo drive designed for precise motion control in industrial automation systems. As part of ABB’s extensive automation portfolio, this drive integrates seamlessly with ABB’s ACS880 and ACS580 series inverters, providing reliable and accurate motor control for applications ranging from robotics to CNC machining. Its core functionality lies in converting electrical signals into mechanical motion, enabling precise positioning and speed regulation for motors up to 15 kW.

In automation setups, the ABB 5SHX2645L0004 typically serves as a critical interface between control systems and motor actuators. Whether deployed in manufacturing lines for robotic arm control or in packaging systems for conveyor belt synchronization, it ensures stable and responsive operation under demanding conditions. The drive’s compact design and lightweight construction make it ideal for space-constrained installations, while its rugged build quality ensures long-term reliability in harsh environments.

What makes the ABB 5SHX2645L0004 particularly valuable is its combination of precision, adaptability, and durability. With advanced feedback mechanisms and robust diagnostics, it delivers consistent performance even in high-vibration and high-temperature settings. Its compatibility with ABB’s RobotStudio software allows for easy programming and monitoring, reducing commissioning time and operational costs.

5SHX2645L0004

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB 5SHX2645L0004 |

| Manufacturer | ABB |

| Product Type | Servo Drive |

| Power Supply | 3-phase AC 380–480 V, 50/60 Hz |

| Output Power | 15 kW |

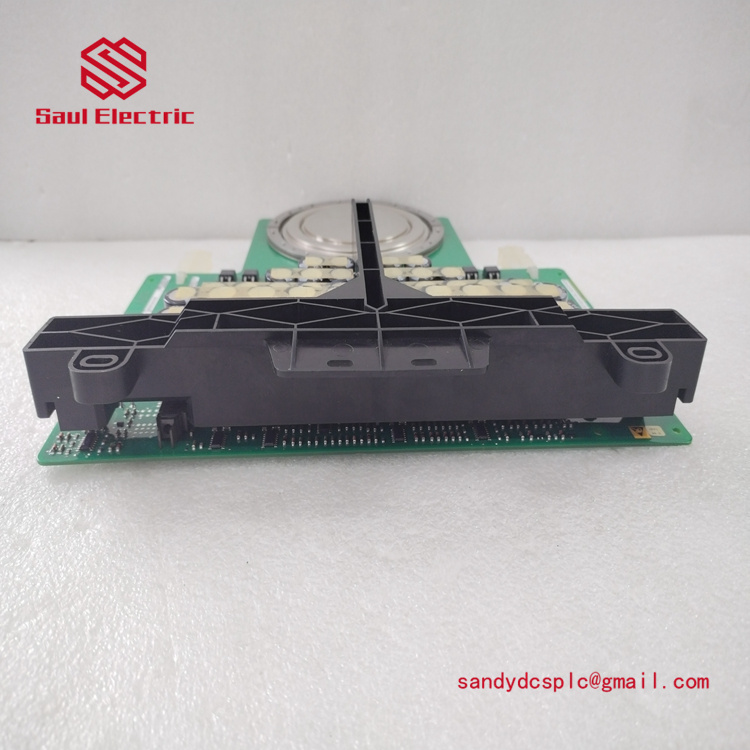

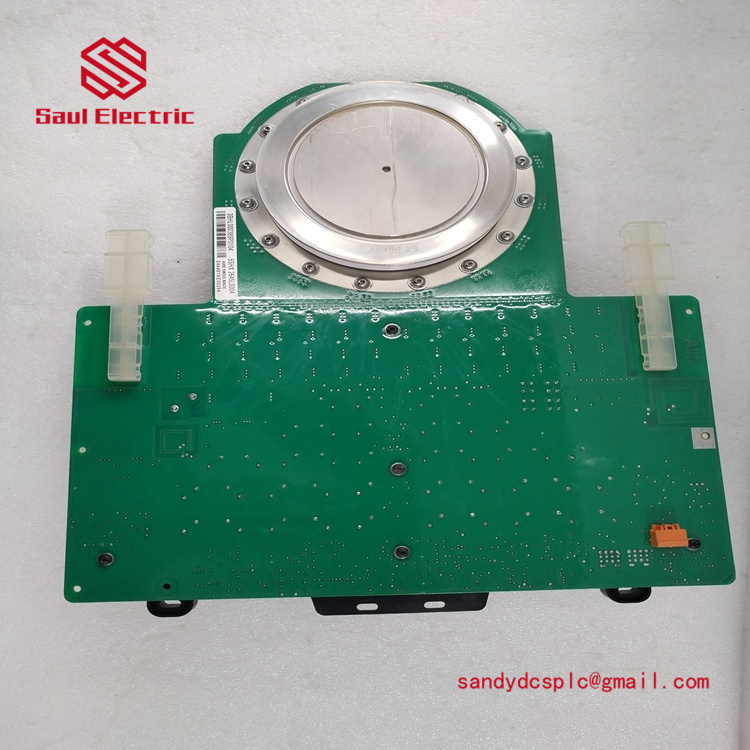

| Dimensions (W x H x D) | 260 x 180 x 125 mm |

| Weight | 5.2 kg |

| Communication Protocols | Modbus TCP/IP, Ethernet/IP, Profibus DP |

| Operating Temperature | -10°C to +50°C |

| Protection Rating | IP20 (standard), IP66 (with optional enclosure) |

| Mounting Type | Wall or panel mounting |

| Motor Compatibility | Up to 15 kW synchronous or asynchronous motors |

| Certification | CE, UL, CUL, EAC |

Key Features and Benefits

The ABB 5SHX2645L0004 excels in environments demanding precise motion control and reliability. Its advanced servo algorithm ensures sub-millisecond response times, making it ideal for applications requiring rapid adjustments, such as robotic welding and CNC toolpath execution. The drive’s integrated diagnostics continuously monitor motor temperature, torque, and speed, providing early warnings for potential issues and reducing unplanned downtime.

One of its standout features is the ability to operate with multiple motor types, including synchronous reluctance and induction motors, enhancing its versatility across industries. The ABB 5SHX2645L0004 also supports ABB’s patented Direct Torque Control (DTC) technology, which automatically compensates for load variations and ensures smooth motion even under fluctuating conditions.

The drive’s compact form factor and lightweight design simplify installation in confined spaces, such as robotic cells or mobile machinery. Its IP66-rated optional enclosure protects against dust and water ingress, ensuring reliability in outdoor or wet environments.

For system integrators, the ABB 5SHX2645L0004 offers seamless compatibility with ABB’s ACS880 inverters and RobotStudio software. This reduces wiring complexity and engineering time, while its modular design allows for easy scalability in large-scale automation projects.

Application Scenarios

In automotive manufacturing, the ABB 5SHX2645L0004 is widely used for robotic arm control in welding and painting processes. Its high-precision motion control ensures consistent assembly quality and reduces material waste.

In food and beverage processing, the drive controls conveyor belts and packaging machines, providing smooth and synchronized motion to prevent product damage and improve production efficiency.

For CNC machining centers, the ABB 5SHX2645L0004 interfaces with spindle motors and feed drives, delivering precise toolpath execution and reducing machining errors. Its high-torque output ensures stable cutting even in hard materials.

In smart infrastructure projects, the drive regulates hydraulic pumps and valves in building automation systems, ensuring energy-efficient and responsive operation.

5SHX2645L0004

Related Models

-

ABB 5SHX2645L0005 – Higher-power variant rated up to 22 kW for heavy-duty applications.

-

ABB 5SHX2645L0003 – Lower-power model suitable for lightweight automation tasks.

-

ABB ACS880-01-0150-4 – Companion inverter for extended motor control capabilities.

-

ABB IRC5 Compact – Robotic controller optimized for integration with this drive.

-

ABB 5SHX2645L0004R – Ruggedized variant designed for marine and offshore applications.

-

ABB 5SHX2645L0004E – Extended temperature range model rated up to +60°C.

Installation and Maintenance

Before installing the ABB 5SHX2645L0004, ensure the cabinet environment meets temperature and humidity specifications. Mount the drive on a wall or panel with adequate airflow clearance to prevent thermal throttling. Ground the chassis to shield against electromagnetic interference, and use motor cables compatible with the drive’s output power.

For maintenance, conduct quarterly firmware updates via the integrated Ethernet/IP interface. Inspect motor connections annually for corrosion and retighten as needed. Replace cooling fans every 3 years to maintain thermal performance. Regularly clean the drive’s ventilation openings to prevent dust accumulation.

Product Warranty

ABB provides a 3-year limited warranty for the ABB 5SHX2645L0004, covering manufacturing defects and performance issues. Global support teams offer 24/7 technical assistance, including remote diagnostics and on-site service for critical failures. Extended warranty plans and calibration services are available to extend asset lifecycle. ABB’s commitment to quality ensures the drive meets stringent industry standards, minimizing total cost of ownership and maximizing operational uptime.

ABB 5SHX2645L0004