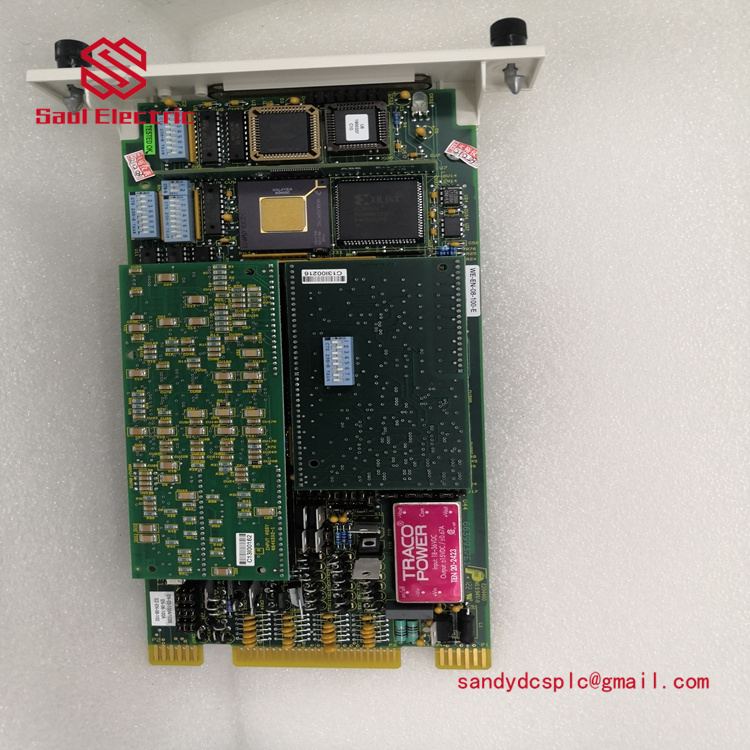

ABB SPHSS03 Product Description

Product Overview

The ABB SPHSS03 is a high-performance hydraulic servo module designed for precise motion control in industrial automation systems. As part of ABB’s extensive automation portfolio, this module integrates seamlessly with ABB’s Harmony Rack system and Symphony Plus controllers, providing reliable and accurate hydraulic actuation for critical processes. Its core functionality lies in converting electrical signals into hydraulic power, enabling precise valve positioning and flow control in applications ranging from power generation to process industries.

In automation setups, the ABB SPHSS03 typically serves as a critical interface between control systems and hydraulic actuators. Whether deployed in power plants for turbine control or in manufacturing lines for robotic automation, it ensures stable and responsive operation under demanding conditions. The module’s compact design and lightweight construction make it ideal for space-constrained installations, while its rugged build quality ensures long-term reliability in harsh environments.

What makes the ABB SPHSS03 particularly valuable is its combination of precision, adaptability, and durability. With advanced feedback mechanisms and robust diagnostics, it delivers consistent performance even in high-vibration and high-temperature settings. Its compatibility with ABB’s System 800xA platform allows for easy integration with existing automation frameworks, reducing engineering time and operational costs.

ABB SPHSS03

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB SPHSS03 |

| Manufacturer | ABB |

| Product Type | Hydraulic Servo Module |

| Power Supply | 24 VDC ±10% |

| Weight | 0.6 kg |

| Dimensions (W x H x D) | 297.18 x 35.56 x 175.26 mm |

| Communication Protocol | Modbus RTU, Profibus DP, HART |

| Operating Temperature | -20°C to +70°C |

| Protection Rating | IP65 (front side), IP20 (rear side) |

| Mounting Type | DIN rail or panel mounting |

| Hydraulic Pressure Range | 0–350 bar |

| Certification | CE, SIL 2 (IEC 61508), ISO 13849-1 Category 3 PL d |

Key Features and Benefits

The ABB SPHSS03 excels in environments demanding precise hydraulic control and reliability. Its advanced servo algorithm ensures sub-millisecond response times, making it ideal for applications requiring rapid adjustments, such as turbine load balancing and valve stroking. The module’s integrated diagnostics continuously monitor hydraulic pressure, temperature, and flow rates, providing early warnings for potential issues and reducing unplanned downtime.

One of its standout features is the ability to operate with multiple hydraulic fluids, including mineral oil and synthetic esters, enhancing its versatility across industries. The ABB SPHSS03 also supports ABB’s patented Adaptive Gain Control technology, which automatically compensates for environmental changes and system wear, ensuring consistent performance over time.

The module’s compact form factor and lightweight design simplify installation in confined spaces, such as offshore platforms or mobile. machinery Its IP65-rated front panel protects against dust and water ingress, ensuring reliability in outdoor or wet environments.

For system integrators, the ABB SPHSS03 offers seamless compatibility with ABB’s Symphony Plus controllers and Harmony I/O systems. This reduces wiring complexity and engineering time, while its modular design allows for easy scalability in large-scale automation projects.

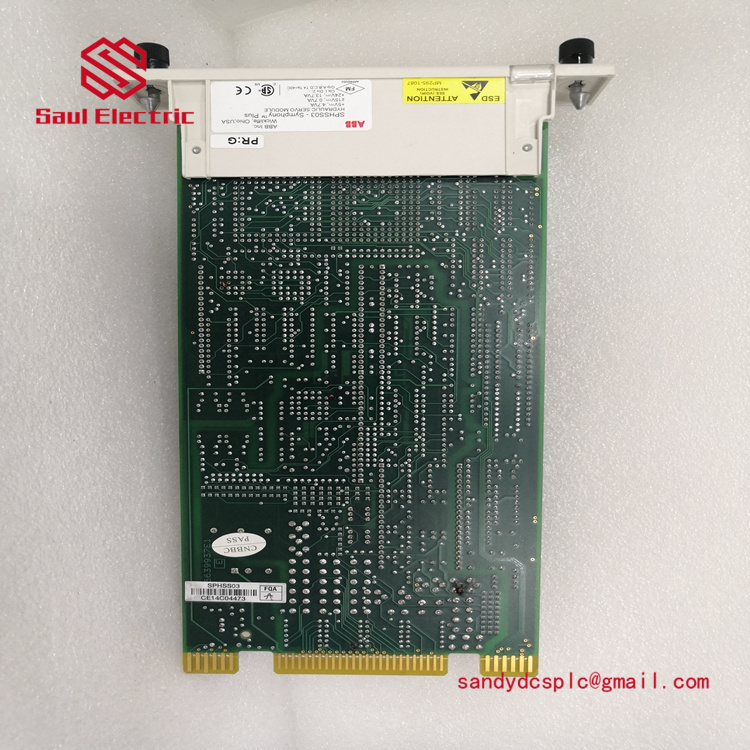

SPHSS03

Application Scenarios

In power generation plants, the ABB SPHSS03 is widely used for turbine governor control, ensuring precise steam or gas flow regulation to maintain stable power output. Its SIL 2 certification makes it suitable for safety-critical applications like emergency shutdown systems.

In oil and gas refineries, the module controls hydraulic actuators for pipeline valves and pressure relief systems. Its ability to handle high-pressure fluids and extreme temperatures ensures safe and efficient operation in demanding environments.

For discrete manufacturing, the ABB SPHSS03 interfaces with robotic cells and material handling systems, providing precise hydraulic power for grippers, conveyors, and presses. Its compatibility with Profibus DP aligns with Industry 4.0 standards, enabling data exchange with MES platforms.

In smart infrastructure projects, the module regulates hydraulic systems in building automation, such as HVAC dampers and water treatment valves, ensuring energy-efficient and responsive operation.

Related Models

-

ABB SPHSS13 – Next-generation model with enhanced diagnostics and support for IoT connectivity.

-

ABB IMHSS03 – Legacy model with basic functionality, suitable for retrofits.

-

ABB SPHSS03R – Ruggedized variant designed for offshore and marine applications.

-

ABB SPHSS03H – High-temperature variant rated up to +85°C.

-

ABB SPHSS03L – Low-power variant for battery-operated or energy-efficient systems.

-

ABB SPHSS03E – Enhanced model with energy recovery features for sustainability initiatives.

-

ABB SPHSS03C – Companion module for closed-loop hydraulic systems.

Installation and Maintenance

Before installing the ABB SPHSS03, ensure the cabinet environment meets temperature and humidity specifications. Mount the module on a DIN rail with adequate airflow clearance to prevent thermal throttling. Ground the chassis to shield against electromagnetic interference, and use hydraulic lines compatible with the operating pressure range.

For maintenance, conduct quarterly firmware updates via the integrated HART interface. Inspect hydraulic connections annually for leaks and retighten as needed. Replace seals every 3 years to maintain hydraulic integrity. Regularly clean the module’s ventilation openings to prevent dust accumulation.

Product Warranty

ABB provides a 2-year limited warranty for the ABB SPHSS03, covering manufacturing defects and performance issues. Global support teams offer 24/7 technical assistance, including remote diagnostics and on-site service for critical failures. Extended warranty plans and calibration services are available to extend asset lifecycle. ABB’s commitment to quality ensures the module meets stringent industry standards, minimizing total cost of ownership and maximizing operational uptime.

SPHSS03